Sinopec Group is a super-large petroleum and petrochemical enterprise group. With 20 years working in energy and chemical fields, Sinopec has grown as the largest refining company in the world and its total number of gas stations was rank third place on Fortune's Global 500 List in 2017.

.jpg)

On average, Sinopec Group processes about 250 million tons of oil and produced 150 million tons of oil products for a year production which explains why Sinopec always has a huge demand for qualified human resources in the oil and gas sector.

However, there was a shortage of laborers possessing good technical skills in Kuwait which created big problem for Sinopec. Fortunately, Sinopec has found Vietnam Manpower Agency supplying qualified Vietnamese workers to solve their labor shortage once and for all.

.jpg)

Within less than 1 year, Sinopec has had three times cooperated with Vietnam Manpower recruiting Vietnamese workers for two positions: Welders and Fitters in oil and gas fields. Three successive recruitments with more than 500 employees in eight months are indicative of long-term and trusted cooperation between Sinopec Kuwait and Vietnam Manpower.

|

Recruitment periods |

Demand |

Position |

|

1st Recruitment: January of 2018 |

>100 workers |

Welders and Fitters |

|

2nd Recruitment: March of 2018 |

>150 workers |

Welders and Fitters |

|

3rd Recruitment: August of 2018 |

>300 workers |

Welders and Fitters |

For the third cooperation on the 13th August 2018, the recruitment took place at three locations in Vietnam including Hanoi, Haiphong and Nghe An within 10 consecutive days for four positions: Welders, Foremen for welders, Fitters and Foremen for fitters which add up more than 300 candidates in total – the biggest number of workers recruited by Sinopec Kuwait so far and predicted to continuously increase in the future.

The welding and painting process is strictly organized and closely monitored not only by the Sinopec representatives but also by the third quality inspection parties: Bureau Veritas China and Apave Vietnam. As a result, the quality of the workforce of the selected final workers is ensured and highly effective in the workplace.

The process of welding test conduction: 7 steps

.jpg)

Step 1: Announce the welding process and inspect the quality of the equipment at the workshop. The tube test specifies a pipe thickness of 18 mm.

.jpg)

Step 2: Conduct the 6 inch pipe welding test and select the candidates whose products meet the quality standard demand.jpg)

.jpg)

Step 3: The one selected in step 2 will continue to participate in the 2 inch pipe welding test. Each candidate was closely monitored by representatives of Sinopec and Bureau Veritas China.

.jpg)

.jpg)

Step 4: The third party will take visual test at the 2 inch pipe welding products and select for further inspection

.jpg)

.jpg)

Step 5: Bring selected products in step 4 to the laboratory of Apave Vietnam Welding Inspection Center for a radio graphic test to inspect the internal weld structure, ensuring the product is not porous. This entire process takes about 2 days to complete

.jpg)

Step 6: Sinopec Representatives base on Apave Vietnam welding inspection to give the final results of the candidates passing the welding test.

.jpg)

.jpg)

Step 7: Selected candidate after entering Kuwait will be granted a standard welding certificate by Bureau Veritas China to join the project.

.jpg)

The process of fitter test conduction: 4 steps

.jpg)

Step 1: Reading technical drawing test

.jpg)

Step 2: Bending steel wire according to the technical drawing to test the worker’s theoretical knowledge

.jpg)

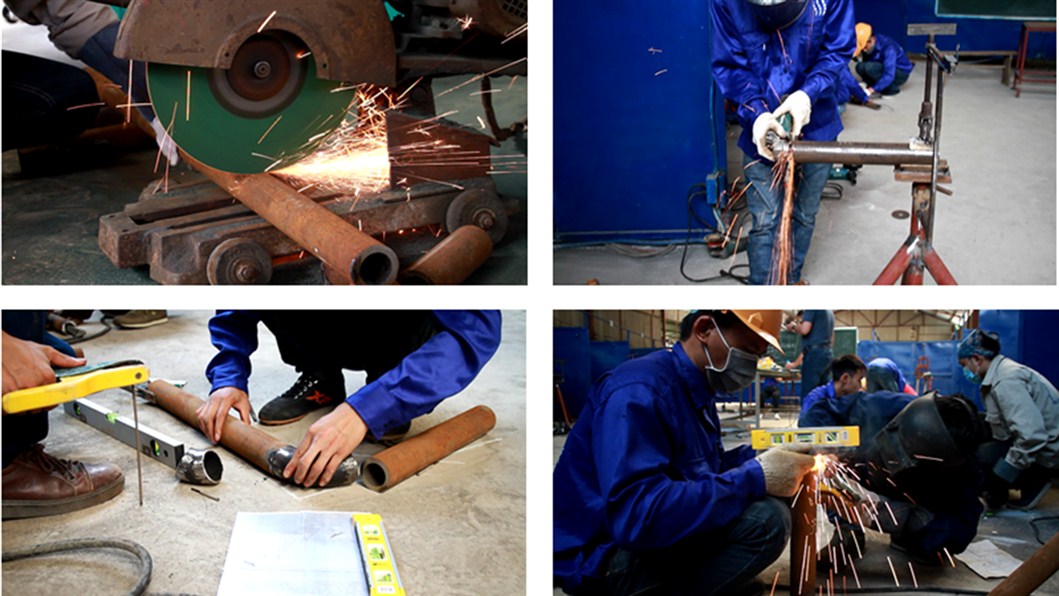

Step 3: Carry out practical test including: cutting, grafting, attaching parts according to technical drawings

.jpg)

Step 4: Inspection and measurement of the accuracy of the final assembled products and grading on the A and B scale

.jpg)

The recruitment of more than 300 employees was a successful collaboration between Sinopec and Vietnam Manpower. Within 10 days of the entrance exam, screening and summing up the list of winners, this collaboration brought Kuwait market a large number of skilled workers, good working attitude and high productivity.

Representatives from Bureau Veritas China said: Welding skills of Vietnamese welders are quite good. The test results show that the welds are uniform and not porous within the weld, which is very important in the oil and gas industry by ensuring the technical standards are very high. Welding quality has a great impact on the operation and quality of the final product. Fortunately, 90% of the welding products of Vietnamese workers meet the quality standards desired by Bureau Veritas China.

.jpg)

Sinopec representatives also said: This is a successful cooperation which not only did resolve the shortage of laborers in Kuwait but also gave Sinopec a high quality human resource at a very affordable cost and promising to bring many economic benefits to Sinopec Group in future. He hoped that after this third cooperation, Vietnam Manpower will continuously improve the quality of manpower supplying services and both parties will have more cooperation in the future.

For more information, please contact:

Ms. Lana Phung

Hotline: (+84) 949 594 116

Email: lana@vnmanpower.com