What is the PDCA cycle?

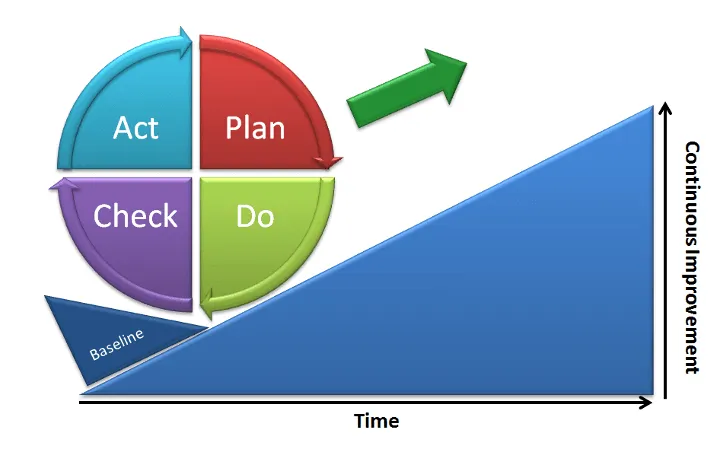

The PDCA cycle is the synthesis of a series of continuous activities in business operation: Planning (Plan); Do (Do); Verify (Check) and adjust and improve (Act). This process that is carried out on a continuous basis is known as “iterating the PDCA Process”.

This process is based on a sequence of actions including:

-

Plan: Make a plan, at this step it is necessary to define the goals, resources, implementation time and methods to achieve the desired goal.

-

Do (Implement plan): Implement the detailed plan given.

-

Check: Based on the work report results compared with the target to check and evaluate the results.

-

Act: Through the evaluation results obtained, there will be appropriate effects to adjust to start a new cycle with new input data.

PDCA is also known as the governance cycle. This cycle can be applied iteratively and thoroughly to any business regardless of the business sector.

PDCA . cycle

Example of PDCA . cycle

Here are some examples of the PDCA cycle when applied to the actual work of the job:

|

Plan |

Plan to organize a care project, evaluate the level of customer satisfaction with the business. In this step, businesses need to ensure the following issues:

|

| Do | Implement the implementation of the plan given in the first phase. |

| Check | Evaluate the process with criteria such as the number of customers taken care of, the rate of complaints recorded, the amount of complaints handled, and consumer evaluation after project completion. |

| Act | Review the results achieved against the set goals. From there, there is a plan to improve the shortcomings to apply in future programs. |

In fact, the PDCA cycle has been applied by many large enterprises in the world, such as:

Nike

Nike has implemented a lean management approach to optimize its manufacturing processes. However, working conditions and regulations at Nike are still not really good and effective. So, Nike decided to apply PDCA. This process has empowered Nike employees, partners, and customers to improve working conditions in their manufacturing plants with a scoring system that measures the performance of manufacturing facilities.

With the PDCA process, Nike has drastically improved working conditions in factories and factories, eliminating unnecessary costs. Lean governance and PDCA have doubled Nike's growth, from $100 billion in 2015 to $200 billion in 2021.

Mayo Clinic

Mayo Clinic is a non-profit hospital established in 1889 and has been ranked as the number 1 hospital in the US for many years in a row. Mayo Clinic used Kaizen and PDCA in tandem to refine treatments, manage patient records, and reduce customer wait times. As a result, the time to examine and test patients is reduced from 7.3 hours to 3 hours after more than 1 year of applying the two methods above. In addition, the hospital's total inventory of medical supplies and equipment also decreased by 31%.

Advantages and disadvantages of applying the PDCA cycle in the enterprise

The PDCA cycle plays an important role in enterprises applying an effective quality management system according to ISO 9001 and is decisive to the success or failure of the business.

- Change management

The PDCA cycle not only encourages businesses to ensure quality and performance, but also helps managers understand the efficiency of work processes, thereby changing the way of management to optimize. goal achieved.

- Process improvement

The PDCA cycle provides continuous improvement precisely because it operates in a cyclical manner. Each task in your project or activity will go through the same phase over and over again, ensuring that errors and omissions can be detected and corrected in time to adapt to the needs and realities of your business. company.

- Performance Management

Through the PDCA cycle, the work and work performance of each company employee will be monitored and managed, performance assessed and adjusted in time.

- Quality management

One of the main uses of the PDCA cycle is quality management. The PDCA's continuous feedback-performance loop enables data collection planning and data statistical analysis to verify and prioritize problems or root causes of problems. It defines the means to reduce the deviation between the current state and the desired state.

- Maintain control over the project

The PDCA cycle is a tool that helps project managers maintain greater control over a given project in many ways.

Besides the outstanding advantages, PDCA still has certain disadvantages:

- Deploying PDCA is only really useful when the process is repeated many times, if it is only implemented once, it will only waste the organization's resources.

- The application of PDCA is suitable and flexibly applied to many business models, however, PDCA is not suitable for short and urgent jobs and projects.

How to apply PDCA successfully

Step 1: Plan

- Planning is the first and foremost step in the PDCA process. A detailed and accurate plan will help businesses orient the next activities in the PDCA implementation process.

- An accurate and clear plan, specifically, will limit to the maximum extent adjustment and improvement activities. At the same time, activities can also be controlled more effectively.

- This planning step includes many activities such as defining goals, resources and implementation methods before going into official production. This helps businesses effectively use resources, cut costs incurred in the management process, and create competitiveness for businesses.

The planning step includes small, specific steps:

- Set goals for the project.

- Develop a detailed description of the task.

- Form a team to do the work and predict the completion date.

- Determine the required data during implementation.

- Clearly analyze the work, performer, completion deadline, operating style, ... to serve as a basis for the following steps to operate in the right direction.

Step 2: Do (Implement according to the plan)

- At this stage, the enterprise begins to implement the activities of the plan set out in the previous stage. At this stage, the enterprise implements the plan by using tools and means to accomplish the set goals.

- After identifying the points to improve, the business needs to make a plan to implement. Managers need to answer a number of questions when implementing a plan, specifically:

-

- What points need improvement?

- What steps do managers need to take to complete the plan?

- When is the deadline to complete the plan?

Step 3: Check (Check)

- This is the stage to ensure that the implementation process is effective or not, ensuring that the set goals are achieved.

- This phase performs activities such as checking, monitoring, collecting and evaluating the shortcomings. This is done in order to detect the causes and provide timely solutions.

- At this step, businesses need to:

-

- Evaluate process performance.

- Look for ways to improve.

Step 4: Act

- Implement improvement of defects.

- Look for ways to limit the problem.

- This stage allows the activities of the business to be synchronized. At the same time, errors in the process are also corrected.

- This stage helps the quality of the product to match the actual situation with the business. As a result, the gap between customer expectations and actual quality is achieved.

PDCA cycle in production and quality management

The PDCA cycle is widely applied to the production process and quality management according to ISO 9001. Specifically, this process is implemented in association with clauses 4 - 10 of the ISO 9001 standard as follows:

- Plans:

Enterprises need to ensure that the cycle is performed once a year if they want to apply PDCA to quality management. From there, the execution plan is guaranteed to be relevant and there are appropriate improvements in real time.

Planning according to ISO 9001 is specified as follows:

| Article 4: Organizational context |

|

|

Article 5: Leadership |

|

| Article 6: Planning |

|

| Article 7: Support |

|

- Do

Enterprises take action to realize the set plan. This is partly in clause 7 and mostly in article 8 of ISO 9001, specifically:

-

- Article 7.2: Capacity.

- Article 8:

-

- Planning and implementing control.

- Requirements for products and services of the enterprise.

- Design products and services to meet requirements.

- Control objects outside the business.

- Producing and providing suitable products and services.

- Through products and services.

- Check:

Enterprises need to regularly check and evaluate the overall activities of the QMS. This activity is covered in clause 9 - evaluation of operating terms with specific requirements as follows:

-

- Collect information, perform assessments, measure customer satisfaction.

- Organize internal audits.

- Management reviews and comments.

- Act:

After the assessment, the business needs to make a review and improvement. This process may include troubleshooting and handling problems that arise during operation. In ISO 9001, this process is described in detail as follows:

-

- Nonconformities and stipulations of remedial measures.

- Continuous improvement.

Replies to This Discussion